1. We are only focus on the designing and researching for M.Y gyratory screen sieve.

2.We supply and design the screening and separation solution for different project.

3.We try our best to offer you the reasonable screening equipment.

Features:

1. It is convenient for replacing the screen mesh and save the equipment down time.

2.Screening precision is high

3.Compare other precision screening equipment, its capacity is larger.

4.Installation and operation is convenient.

- Production

- Principle

- Application industry

- Video

- Brochure download

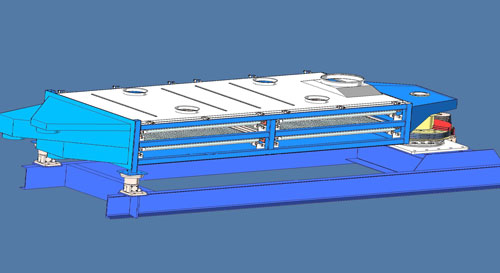

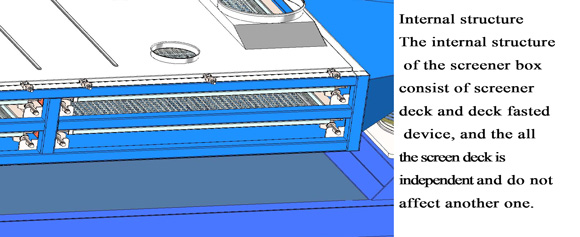

MPG series gyratory screen sieve is similar with M serial gyratory screen such as the screening principle, screening efficiency and application, just except the screen deck structure.

In some customer application technical process, the customer need always renew the screen mesh, if the renew time for screening mesh is too long, or it is very difficult for replacing the screen mesh, it will take too much time for stopping the equipment work if replacing mesh for several times, so it will affect the production output at last, the MPG series gyratory screen sieve is for solving above problem, and this screener has following features:

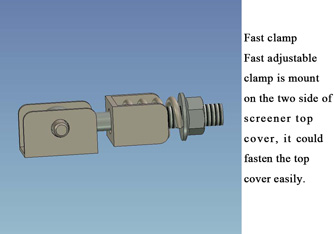

1.The operation of replacing screen mesh convenient, one worker could finish the mesh replacing work within 10 mins for one complete equipment, which save the equipment stop time and save the labor energy cost, it increase the screening capacity at last.

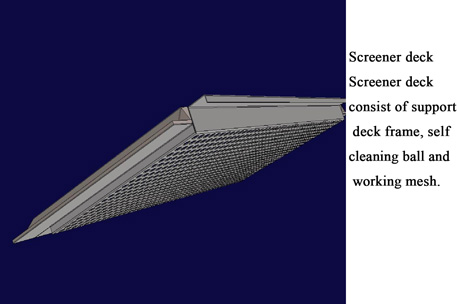

2.One layer screener deck consist several little piece screen deck, if some section is worn out, we just need renew the broken little piece screen mesh but not the complete layer screen mesh, so it save the mesh cost.

3.The area of each little piece screen mesh is 1/8 –1/2 of complete layer screener deck, so it do not take much room when renewing the screen mesh.

4.It do not injure previous screen mesh when replace it, so we could recycle it.