Compount Fertilizer Screening

Compount Fertilizer Screening Equipment

The compount fertilizer is one huge range fertilizer include NPK, monoammonium phosphate, diammonium phosphate, potassium nitrate, urea ammonium phosphate, potassium dihydrogen phosphate, ammonium nitrate phosphate, phosphate nitrate, ammonium chloride phosphate, ternary compound fertilizer of nitrogen, phosphorus and potassium, ammonium phosphate, etc.

During the fertilizer production process, it need screening equipment for grading, scalping or fines removing.

But the dust of the fertilizer always easy to absorb the moisture from the air then become sticky, it is easy to ahere to the mesh wire, then block the mesh aperture.

The the screener need to be with self-cleaning device to reduce the mesh aperture blockage problem.

Our MHG model side doors access gyratory screener not only with self-cleaning balls for the fertilizer, it also could change mesh from two side of the screener box, that means the worker could finish the mesh changing work within 10 mins, it let the equipment down time as short as possible. It is one proper compount fertilizer screening equipment.

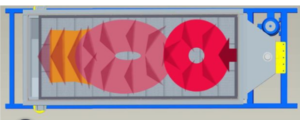

self-cleaning ball structure

compound fertilzer screening equipment