Frac Sand Screening Equipment

Frac Sand Screening Equipment

Overview of MH and MHG Gyratory Screen Separator for Frac Sand:

Gyratory sifter is one proper frac sand screening equipment ,for frac sand is also called square gyratory screen, gyratory screener, square swing screen, sweco type gyratory screen, gyratory separator etc.

Simple pursuit of sieving accuracy will be at the expense of yield, while the pursuit of large yield will decrease the accuracy. Gyratory sifter for frac sand is a kind of screening equipment with the characteristics of low failure rate, low downtime rate, low cost, and high output, high precision, high efficiency,, which is specially designed for the above problem.

Gyratory sifter for frac sand is widely used in the industries including chemical, metallurgy, ferrous metal, non-ferrous metal, food and abrasive.

The screening machine can be equipped with one to four layers of screen

Working Principle of Gyratory screening equipmentfor Frac Sand:

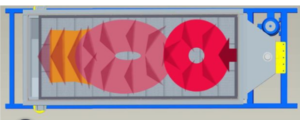

The total gyratory movement of the square gyratory sifter can rapidly spread, stratify and separate the material. The unique gyratory motion can quickly spread the material across the full width of screen at the feed end, driving the particles move forward contact with the screen surface. The large horizontal amplitude can improve the sieving effect of the near-size particles, and can improve the material handling capacity of the machine.

frac sand screening

frac sand sifter equipment