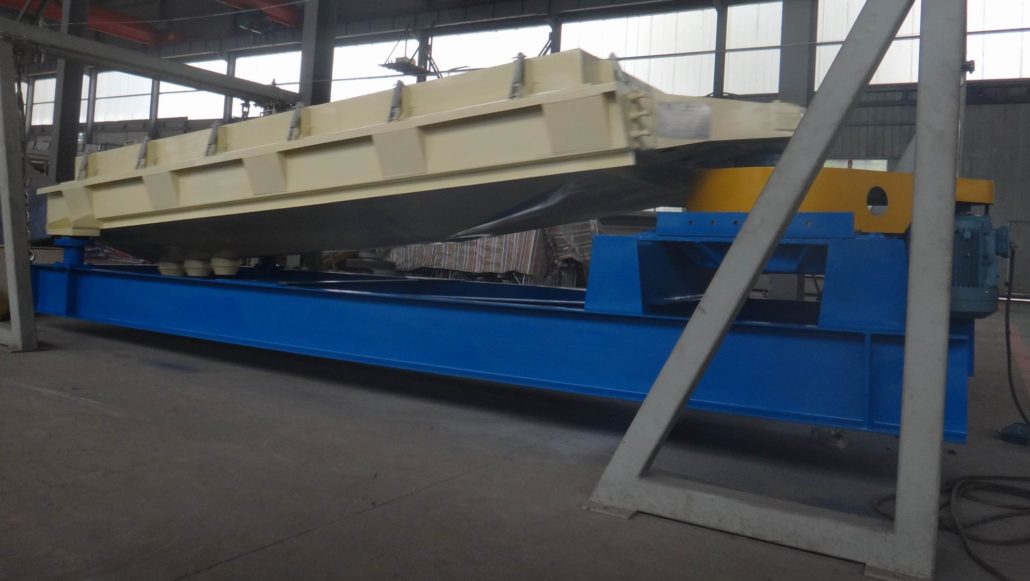

Third set side door access gyratory sifter exportation

We prepare to export our third set side door access gyratory sifter to one customer for perlite screening.

We have supplied one such model sifter for perlite screening and separation.

As we know, the perlite bulk density is very little, if screening perlite with high frequency vibrating sifter, the high frequency vibration may bring much more perite dust into the air, it is not good for screening. So low frequency gyratory screener is one best choice.

Then the perlite pellets may block the mesh aperture, the gyratory sifter fit with self-cleaning ball, so it could clean the mesh if the pellets block the mesh aperture.

But the material may block the mesh at last may because the moisture , the capacity factory, the operator need bring the mesh out the screen to clean the mesh via hand or other method, it is the largest advantage of the side doors access gyratory sifter, because it could open the screener box from two side, and one little screener deck is very little and light, the work is very safe and easy, one worker could finish the mesh changing and cleaning work.

side door access sifter exporation